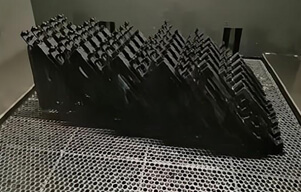

CNC Machining in PEEK – What is PEEK Plastic?

Polyether ether ketone (PEEK) is a high polymer composed of repeating units containing one ketone bond and two ether bonds in the main chain structure. PEEK is a special engineering plastic with excellent performance. Compared with other special engineering plastics, it has many significant advantages, such as high temperature resistance, excellent mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardancy, peel resistance, and radiation resistance. It is widely used in aerospace, automobile manufacturing, electrical and electronic, medical and food processing and other fields.

Types and Properties of Machining Peek Plastic Material

Machining Peek plastic materials are available in both bar and plate forms, which makes it suitable for a series of custom CNC machining services including CNC Milling, CNC Lathing, CNC cutting. CNC sawing, drilling, milling and turning. There are many types of Machining PEEK materials, such as medical grade Peek: PEEK-1000, glass filled peek: PEEK-GF30, carbon filled peek: PEEK-CA30, bearing grade peek: PEEK-HPV, and other types.

Medical grade Peek: PEEK-1000

Manufactured from pure polyetheretherketone resin, PEEK-1000 material has the toughest and best impact resistance of all PEEK grades. PEEK-1000 can be sterilized by the most convenient sterilization methods (steam, dry heat, ethanol and gamma rays), and the raw material composition of PEEK-1000 complies with EU and US FDA regulations on food compatibility. These characteristics make PEEK-1000 machined parts widely applied in the medical, pharmaceutical and food processing industries.

Glass Filled Peek: PEEK-GF30

PEEK-GF30 is a reinforced plastic filled with 30% glass fiber, which has better rigidity and creep resistance than PEEK-1000, as well as better dimensional stability. Glass Filled Peek is an ideal material for manufacturing structural parts. It can withstand fixed load for a long time at high temperature. If PEEK-GF30 is used to produce sliding parts, its suitability needs to be carefully checked, because glass fibers may scratch the mating surface.

Carbon Filled Peek: PEEK-CA30

PEEK-CA30 material is filled with 30% carbon fiber reinforcement, which has better mechanical properties (higher elastic modulus, mechanical strength and creep) and more wear resistance than PEEK-GF30. Carbon reinforced PEEK is better than unreinforced PEEK plastic with 3.5 times the thermal conductivity, and Carbon Filled Peek can dissipate heat from bearing surfaces faster.

Bearing Grade Peek: PEEK-HPV

The result of adding PTFE, graphite and carbon fiber makes PEEK-HPV a bearing grade plastic. Its superior friction properties (low coefficient of friction, wear resistance, high peak pressure limit) make it an ideal material for machining parts for friction applications.

Advantages of Peek Machining Services Parts

PEEK materials and its machined parts have many advantages:

PEEK machined parts are self-lubricating. It has a low friction coefficient, can realize oil-free lubrication work, and can work for a long time in oil, water, steam, weak acid and alkali and other media.

Easy to process. It can be used for post-processing such as turning, milling, drilling, tapping, bonding and ultrasonic welding.

PEEK parts are low-smoke and non-toxic. The amount of smoke and poisonous gas is extremely low when burning.

PEEK has excellent high temperature resistance. The United States UL certification, the long-term use temperature is 260 ° C, even when the temperature reaches 300 ° C, it can still maintain excellent mechanical functions

PEEK parts are very resistant to wear. In many extremely harsh environments such as high temperature, high load, and strong corrosion, parts made of PEEK have excellent wear resistance.

PEEK has high strength. It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

PEEK is very corrosion resistant. It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

PEEK parts are resistant to hydrolysis. Immersed in steam at a temperature exceeding 250°C or in high-pressure water, PEEK products can still work continuously for thousands of hours without significant functional degradation.

The electrical function of PEEK parts can still maintain stable and excellent electrical function in a wide range of temperature and frequency.

PEEK CNC Machining Near Me- – PEEK Plastic Machined Parts Manufacturer

YS Rapid is a high quality Chinese CNC plastic machining manufacturer. We are committed to providing various china cnc machining services and small run cnc machining services. We can machine a wide variety of plastic parts, including various grades of PEEK parts. We use multi-axis CNC PEEK machining to ensure timeliness and quality of production. All CNC machined PEEK parts are produced strictly according to customer's drawings. At the same time, our technicians will work closely with you to help you optimize your products in order to get better PEEK plastic machined parts and reduce costs.

Why Choose YS Rapid PEEK CNC Machining Services?

Rich Experience, with over ten years experience in custom precision machining.

Using advanced CNC machines and technologies to ensure the accuracy and consistency of your precision PEEK machining.

Skilled workers and strict quality contro, ensuring the quality of your PEEK machined parts.

Professional sales team to give you prompt response to your inquiry and question.

Broad range of material grade available for your various needs

Multiple surface finishes available

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw