Why Use OEM Precision Auto Lathing Service

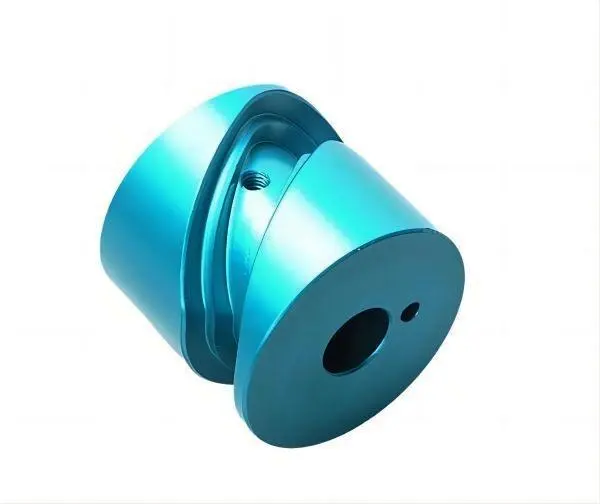

Precision auto lathing service is a kind of custom precision machining service, referring to a specialized machining process in which an automated lathe machine is used to create highly accurate and precise metal parts for the automotive industry. The process involves removing material from a work piece using a cutting tool, which is guided by a computer program to ensure accuracy and consistency.

Precision auto lathing is often used to produce precision mechanical parts such as engine and transmission parts, drive shafts, and other critical automotive components that require high precision and accuracy. The process is highly efficient and can be used to produce large quantities of identical parts with tight tolerances.

Some of the benefits of precision auto lathing service include:

High precision and accuracy: The use of automated lathe machines and computer programs ensures that the parts produced are highly accurate and consistent.

Cost-effective: Precision auto lathing is a highly efficient process that can produce large quantities of identical parts quickly and at a lower cost than other machining processes.

Versatility: Precision auto lathing can be used to produce a wide range of parts, from small and simple to large and complex.

Faster turnaround times: Because precision auto lathing is an automated process, it can produce parts faster than other manual machining processes.

Overall, precision auto lathing is a critical process in the automotive industry that helps to ensure the production of high-quality, reliable, and safe vehicles.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw