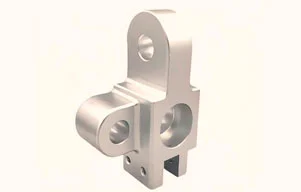

Aluminum Enclosure CNC Machining Process

Aluminum enclosure CNC machining is a process that involves the use of computer-controlled machines to shape and cut aluminum material into precise, custom-designed enclosures. Aluminum is a popular material for enclosures due to its strength, durability, and lightweight properties.

The custom CNC machining process begins with a 3D design file of the enclosure, which is loaded into the CNC machine's software. The software then creates a tool path based on the design, which guides the CNC machine to cut and shape the aluminum material into the desired form.

During the machining process, the CNC machine uses various cutting tools, such as drills and end mills, to remove material from the aluminum block or sheet. The cutting tools move along the programmed tool path and remove material in a precise manner, creating the desired features and contours of the enclosure.

After the machining process is complete, the aluminum enclosure can be finished with additional processes such as anodizing, powder coating, or polishing to improve its aesthetic and functional properties.

Aluminum enclosure CNC machining is a highly accurate and efficient manufacturing process that can produce enclosures with complex shapes, precise tolerances, and high-quality surface finishes. This makes it ideal for producing CNC machining precision parts for various industries, including electronics, aerospace, medical devices, and automotive.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw