Features of Plastic Rapid Prototyping

1. Quick turn-around production

2. It can liberate the hands of engineers and planners. After planning their products, it only need to input the drawings into the CNC machine, and they can quickly obtain the prototype part.

3. Universal applications, plastic prototyping are suitable for almost all field's product development, from electronics, medical, telecommunication, household products, architecture to agriculture industries.

4. Diverse ways of processing for selection. There are multiple ways for processing plastic rapid prototypes which mainly are cnc machining, PU Casting, 3D printing, fast injection molding.

5. Wide Selection of materials. Plastics parts are widely used by products developers in different fields, and there are wide ranges of plastic material for prototypes basing on the different application of the product.

Material Selection of Plastic Rapid Prototyping

ABS Prototype: Prototypes made from ABS plastic prototyping can resist temperature from 60-80℃. and it has the advantages of strong impact resistance, scratch resistance, dimensional stability, at the same time, it is easily machined. ABS CNC prototypes are applied in various fields such as household appliances,diagnosis, automotive, medical devices, and so on!

PC Prototype PC material is also widely used in rapid prototyping, it has plenty of advantages such as High strength and elastic coefficient, high impact strength, High transparency and free dyeing; Good weather resistance; Excellent electrical characteristics; furthermore, it is tasteless and odorless, harmless to human body, in line with health and safety. It is one of the most wide use material in medical equipment industry, automotive industry, electrical industry, etc.

POM prototype: POM prototype has good performance and characteristics, first of all, it has excellent mechanical properties, tensile strength, impact strength, creep resistance, wear resistance and lubricity, has good capacitance, oil resistance, and other properties. POM is often used in machining gears and internal structural parts, mechanical parts, and other structural parts which require high rigidity mechanical strength. POM prototype’s surface can be treated in grinding, sandblasting, polishing and so on.

PMMA Prototype: One of the most advantageous element of PMMA is it has excellent transparency and light transmittance. Acrylic can reach more than 99% transparency after polishing by the hand polishing master; Besides, it has excellent weather resistance, strong adaptation to natural environment, even if it is exposed to sunlight for a long time.Wind and rain will not change its performance, good anti-aging performance, and can be used safely outdoors; PMMA prototype is universally used in Architecture, advertising products, transportation, medical industry, lighting products, and so on.

What are the methods of rapid plastic prototyping?

Rapid plastic prototyping is a cost-effective and efficient way to turn concept designs into physical models. There are several methods commonly used for rapid plastic prototyping. Here are some of the most popular ones:

3D Printing: 3D printing is a popular and widely used method for rapid plastic prototyping creating prototypes. It allows for the creation of three-dimensional objects by adding material layer by layer based on a digital model, which can build plastic prototypes with varying levels of complexity and material properties.

Polyurethane casting: Polyurethane casting is a method commonly used for producing small batch plastic prototypes. It involves creating a silicone mold from a master pattern, typically produced using 3D printing or CNC machining. Liquid plastic is poured into the silicone mold, and a vacuum is applied to remove air bubbles, resulting in detailed replication of the prototype. Polyurethane casting can produce prototypes that closely resemble the final product in terms of appearance and mechanical properties.

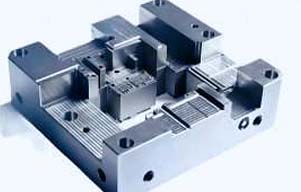

Rapid Injection Molding: Rapid injection molding is a manufacturing process that combines the speed of rapid prototyping with the benefits of injection molding. It involves using a simplified mold made from aluminum or other rapid tooling steels to produce plastic prototypes with shorter lead time and low cost, which is typically used for low-volume production needs, such as small batch runs or initial market testing.

The choice of method depends on factors such as the desired prototype characteristics, project requirements, budget, and time constraints. YS Rapid is a professional rapid prototyping service provider that can offer guidance on selecting the most suitable method based on your specific project needs, such as levels of complexity, accuracy, and material properties, quantity requirement, etc. Contact us today to get an instant quote for your rapid prototyping parts.

How Does Rapid Plastic Prototype Work?

Rapid plastic prototyping is a process that allows for the quick and efficient creation of plastic prototypes. It involves the utilization of various technologies and techniques to transform digital designs into physical plastic models or samples. Rapid plastic prototyping enables designers, engineers, and manufacturers to validate and refine their plastic product designs before moving into full-scale production. Professional prototyping service providers can offer expertise and guidance throughout the process to ensure successful rapid plastic prototyping.

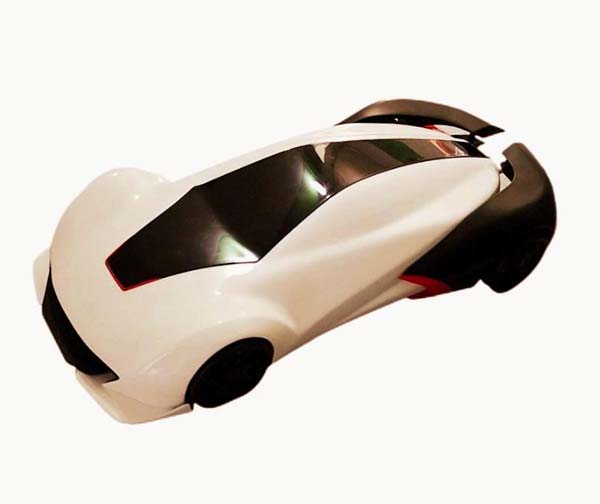

Plastic Rapid Prototyping Details and Options

As a professional China rapid prototyping supplier, YS Rapid has been engaged in custom plastic prototyping for over ten years, and we have been serving hundreds of satisfied global customers in a variety of industries. Our expert team uses the latest China precision machining technology to finish your prototype parts with super quality.

The Extensive Plastic Rapid Prototyping Service We Provide:

Plastic CNC Rapid Precision Machining

Plastic Rapid Prototyping 3D print

Plastic rapid casting prototype by PU casting

Rapid plastic injection molding and insert molding

Extensive Surface finishes including but not limited to: polishing, painting, silkscreen printing, plating and more.

Why Choose YS Plastic Rapid Prototyping Service?

Plastic Rapid Prototyping is an important process in product development to production. To get the right product at lowest cost and shortest time, you need a prototype manufacturing partner you can rely on to create your design to real product within your schedule. Here’s why YS Rapid is a ideal choice:

High Precision Machining. YS Rapid custom CNC milling parts in tight tolerance at +-0.03mm, custom manufacturing as per customer’s specifications

Wide material choice. We can produce prototype parts in wide rang of materials both in plastic & metal

Various surface finishing available: Such as painting, printing, sandblasting, plating, etc.

Competitive price. We provide the most cost-effective and time saving rapid prototyping service.

YS Rapid is a professional China manufacturer providing plastic rapid prototyping services. Our clients can get full range rapid prototyping parts with high quality. If you are looking for rapid prototyping services in China for your plastic prototyping parts, aluminum prototyping parts, or steel prototyping parts, YS rapid can be your excellent partner for custom rapid prototyping Services Supplier in China.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw