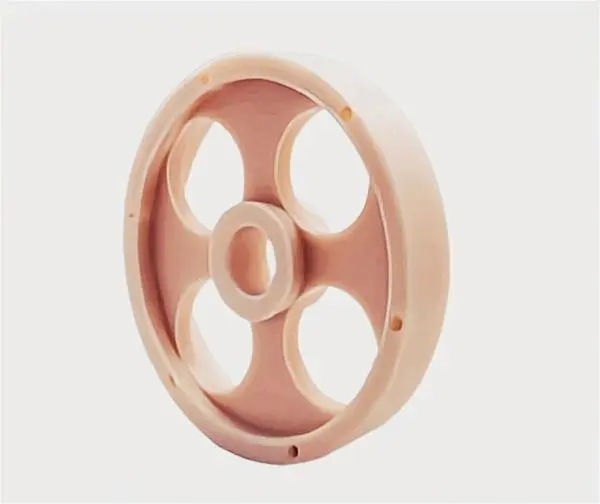

Why Low Volume CNC Machining PEEK Parts for Medical Device

CNC machining PEEK parts in low volume for medical devices offers several benefits in the field of custom medical machining. Here are some of the key reasons:

Cost-effectiveness: Low volume CNC machining is a cost-effective solution for producing small quantities of PEEK parts for medical devices. Traditional manufacturing methods such as injection molding can be expensive for small volumes, making CNC machining a more economical option.

High precision: CNC machining offers a high level of precision and accuracy, ensuring that each PEEK part is manufactured to the exact specifications required for the medical device. This is especially important in the medical industry, where accuracy and quality are critical.

Material versatility: PEEK is a versatile material that can be machined to create complex geometries and features. This allows for the creation of intricate medical device parts that may not be possible with other materials or manufacturing methods.

Short lead times: CNC machining offers shorter lead times than traditional manufacturing methods, making it a good option for medical device manufacturers who need to produce parts quickly.

Customization: CNC machining allows for customization of PEEK parts for specific medical devices, ensuring that they are tailored to the unique needs of the application.

YS Rapid is a low volume plastic CNC machining parts service provider which offer a flexible and cost-effective solution for produce small quantities of high-quality plastic parts with precision and accuracy. Contact us today if you have any inquiry or questions about our service.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw