Quality control measures for rapid prototyping and small batch manufacturing are critical to ensuring that the final product meets the desired specifications. In today's competitive market, where product development and delivery timelines are getting shorter, manufacturers are relying more on rapid prototyping and small batch manufacturing to speed up their product development cycle. However, to maintain quality, it is essential to have a robust quality control system in place. In this article, we will discuss some of the quality control measures that manufacturers should implement when using rapid prototyping and small batch manufacturing.

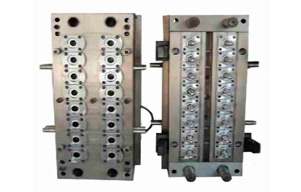

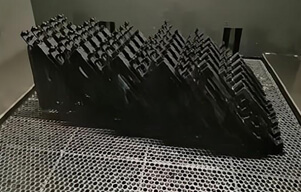

Inspection and testing for CNC machining prototyping

One of the essential quality control measures for rapid prototyping and small batch manufacturing is inspection and testing. Inspections can help detect any defects or anomalies in the prototype or the final product before it goes into mass production. Regular inspection of the production process and the final product can ensure that the product meets the required standards and specifications.

Various testing methods can be used to test the final product's mechanical, thermal, and chemical properties, among other things. Some common testing methods include tensile testing, impact testing, and thermal analysis. CNC machining service providers and rapid prototyping companies often have in-house inspection and testing equipment to perform these tests. However, it is crucial to ensure that the testing methods used are appropriate for the product and its intended use.

Document control for CNC machining prototyping

Another important quality control measure is document control. Document control ensures that the right documents are available to the right people at the right time, and that changes to documents are controlled and recorded. Document control can help manufacturers to maintain consistency in their products, and it can also help them to keep track of the changes made to the product during the development process.

Manufacturers should have a system in place to manage their documents, including design documents, manufacturing instructions, and quality control documents. The system should ensure that the documents are up to date, easily accessible, and that changes to the documents are controlled and recorded.

Calibration and maintenance for CNC machining prototyping

Calibration and maintenance are essential quality control measures for any manufacturing process, including rapid prototyping and small batch manufacturing. Calibration ensures that the equipment used in the production process is accurate and reliable. Regular maintenance of the equipment can help to prevent breakdowns and downtime, which can impact product quality and production schedules.

Manufacturers should have a calibration and maintenance program in place to ensure that their equipment is regularly calibrated and maintained. The program should include regular checks of the equipment, calibration of the equipment when necessary, and maintenance of the equipment based on the manufacturer's recommendations.

Supplier Quality Control

Supplier quality control is an important quality control measure that is often overlooked. Suppliers of raw materials, components, and equipment can have a significant impact on the final product's quality. It is essential to ensure that the suppliers are qualified and reliable and that they meet the required standards.

Manufacturers should have a supplier quality control program in place to ensure that their suppliers meet the necessary standards. The program should include supplier evaluation and qualification, regular supplier audits, and monitoring of supplier performance.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw