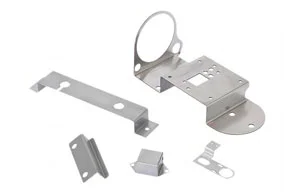

The Techniques of Small Batch Custom Steel Sheet Metal Stamping Parts

Steel sheet metal stamping is a metalworking process that involves creating shapes, cutouts, or other features on steel sheets using a stamping press and a die. There are several techniques used in precision sheet metal stamping, including:

Blanking: This technique involves cutting a flat piece of steel sheet into a desired shape or size. The die used in blanking has a sharp edge that shears the metal to create a precise cut.

Piercing: Piercing is a technique used to create holes or openings in a steel sheet. The die used in piercing has a circular shape and is pressed into the metal to create a hole.

Bending: Bending involves creating bends or folds in the steel sheet to create a 3D shape. The die used in bending has a curved or angled shape to create the desired bend.

Drawing: Drawing is a technique used to create a deep, concave shape in the steel sheet. The die used in drawing has a shape that pulls the metal into a cavity to create the desired shape.

Embossing: Embossing involves creating a raised design or pattern on the surface of the steel sheet. The die used in embossing has a pattern or design that is pressed into the metal to create the desired effect.

Coining: Coining is a technique used to create a high-precision finish on the surface of the steel sheet. The die used in coining has a flat surface that is pressed into the metal to create a smooth, polished finish.

These techniques that frequently used by precision machining factory can be combined to create complex shapes and designs on steel sheets. The choice of technique depends on the desired outcome and the characteristics of the steel being used.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw