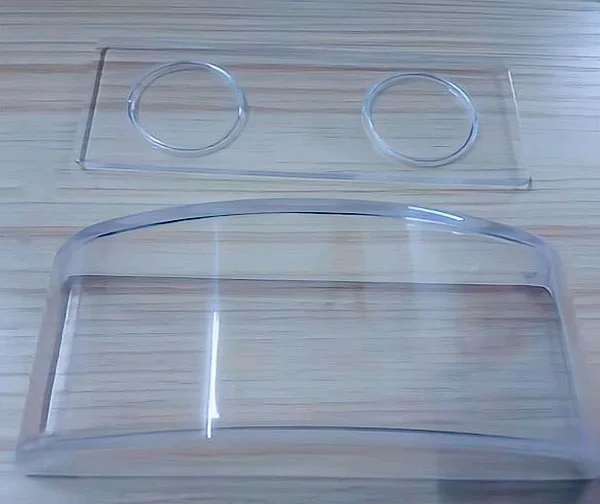

The Process of Producing Transparent PMMA Vacuum Casting Prototype

PMMA (Polymethyl methacrylate) vacuum casting is a common method used for producing prototypes and small-scale production runs of various plastic products. The process involves pouring liquid PMMA into a silicone mold, which is then cured to form a solid part.

Here are the basic steps involved in PMMA casting prototype:

Design the prototype: First, you need to create a design for your prototype using computer-aided design (CAD) software or other design tools. Ensure that the design meets the required specifications and includes all necessary details.

Create the mold: Once you have the design, you need to create a mold for the prototype. You can use a 3D printer to print the mold, or you can use traditional methods like custom CNC machining or fast injection molding.

Prepare the PMMA material: The next step is to prepare the PMMA material for casting. PMMA is available in the form of pellets or powder, which needs to be mixed with a catalyst and poured into the mold.

Pour the PMMA into the mold: Pour the PMMA mixture into the mold and ensure that it fills all the cavities. Once the mold is filled, allow the PMMA to cure and harden.

Demold and finish the part: Once the PMMA has cured, remove the mold from the part carefully. The part may need some finishing touches, such as trimming and polishing, to achieve the desired final shape and appearance.

Test the prototype: Once the PMMA casting is complete, you can test the prototype to ensure that it meets the required specifications. If necessary, you can make adjustments to the design or process before moving on to large-scale production.

Overall, PMMA casting prototype is a relatively simple and cost-effective method for producing prototypes and small-scale production runs of plastic products. It is widely used in industries like automotive, medical devices, consumer goods, and more.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw