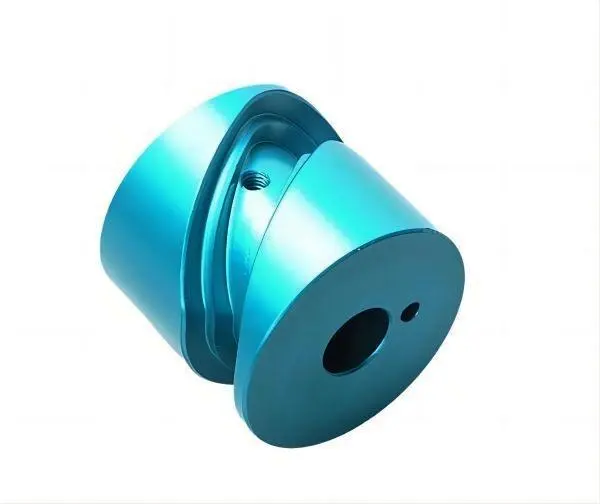

Key steps of Aluminum Motor Shafts CNC Machining

CNC machining is a popular method for producing aluminum motor shafts, which are used in a variety of applications, including motors, generators, and other mechanical devices. Here are some of the key steps involved in CNC machining an aluminum motor shaft:

Material selection: The first step is to select the appropriate grade of aluminum for the shaft based on the specific requirements of the application. Common aluminum alloys used for motor shafts include 6061 and 7075.

Design and programming: The next step is to design the shaft using CAD software and create a CNC program to control the machining process. The program will specify the tool paths, cutting speeds, and other parameters necessary to create the desired shape and dimensions of the shaft.

Set up the CNC machine: The machine must be set up with the appropriate tools, including cutting tools, drills, and taps. The machine must also be calibrated to ensure accuracy and precision.

Machining the shaft: The CNC machine will then cut the aluminum material to create the shape and dimensions of the shaft as specified in the CNC program. This may involve a variety of operations, such as turning, drilling, and threading.

Finishing: Once the shaft is machined, it may be necessary to perform additional finishing operations, such as polishing or anodizing, to achieve the desired surface finish and corrosion resistance.

In all, CNC machining an aluminum motor shaft involves a combination of design, programming, and machining operations to create a high-quality, precise component that meets the specific requirements of the application.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw