Why Using Stainless Steel Machining Parts in Medical Equipment

Stainless steel machining parts are precision mechanical parts that are commonly used in medical equipment due to their strength, durability, and corrosion resistance. Medical equipment often requires high precision and strict compliance with regulatory standards to ensure patient safety, and stainless steel machining provides an effective way to meet these requirements.

Here are some common examples of stainless steel machining parts used in medical equipment:

Surgical Instruments: Surgical instruments, such as forceps, clamps, and scissors, are often made from stainless steel. CNC machining allows for the creation of precise and intricate shapes that can be sterilized and reused multiple times.

Implants: Stainless steel is often used to manufacture implants such as plates, screws, and pins due to its high strength and biocompatibility. CNC machining allows for the creation of customized implants with precise dimensions and geometries to meet the unique needs of each patient.

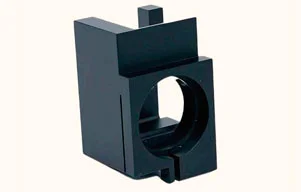

Diagnostic Equipment: Stainless steel machining parts are also used in diagnostic equipment such as X-ray machines and CT scanners. CNC machining allows for the creation of high-precision components that can withstand the rigors of repeated use.

Hospital Equipment: Stainless steel machining parts are used in a variety of hospital equipment, such as bed frames, IV poles, and carts. CNC machining allows for the creation of high-quality and durable components that can withstand constant use and cleaning.

In Summary, stainless steel machining is an effective way to create high-quality and reliable parts for medical equipment. The accuracy of the China precision machining allow for the creation of intricate and complex designs, ensuring that the medical equipment meets the necessary standards for patient safety and functionality.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw