1. According to the effect of the prototype required, it can be divided into Appearance prototype, Structural prototype and Functional prototype:

(1) Appearance prototype: It is mainly used to check the product’s appearance, which requires exquisite appearance, excellent surface finishing & color, appropriate size, shape, and so on.

(2) Structural prototype: It is mainly created to verify the structural rationality of the product, which can be assembled with electronic components, pcb board,wire, etc. Structural prototype has high requirements on dimension and relatively low requirements for surface treatment.

(3) Functional prototype: It can be also called working prototype, which integrates the materials, strength, tolerance, assembly, work mechanisms, manufacturing feasibility, etc. It is required to be most similar function,structure and visual look to the final product.

2. According to manufacturing ways, rapid prototype can be divided into Manual Prototyping & NC Prototyping

(1) Manual prototyping: Some simple prototypes can be manually made with plastic, foam, plastic, paper, wood, and other materials,such rapid prototypes are low-precision, easy making and inexpensive.

(2) NC prototyping (numerical control Prototyping): according to different equipment, it can be divided into LRP prototyping & CNC prototyping.

a. 3D printing prototyping: it is a new manufacturing technology that integrates advanced technologies such as CAD, CAM, CNC, laser, precision servo drive and new materials. Compared with traditional manufacturing methods, it has the following features: high re-productabliity and interchangeability; the manufacturing process are not limited by the geometry of the product; Short lead time--the production time is shorten by 70%; Low cost---The general manufacturing cost is reduced by 50%;

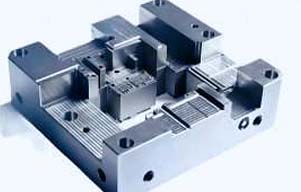

b. CNC Prototyping: It is more high accuracy prototyping using modern machining tools, it is usually made by CNC Milling Machining, CNC lathing, CNC cutting, etc. CNC Prototyping has the advantage of high accuracy, high quality and wide use of materials from plastic to metal.

3. According to materials used, rapid prototype can be divided into Plastic Prototype, Silicone/Rubber Prototype and Metal Prototype:

(1) Plastic prototype: The main material is plastic, such as ABS, PC, POM, PET, Ultem, PTFE, Nylon, PEEK and so on, which were mainly used for making the prototypes of the plastic products, such as computer, printer, air conditioner, telephone, display, television, and so on.

(2) Silicone/Rubber Prototypes: It is mainly made by Vacuum Casting or Silicone compression molding, which is used for protective case, membrane, cover, cleaning parts, sealing, and so on.

(3) Metal Prototype: The main material are aluminum alloy, brass, bronze, stainless steel, carbon steel, etc. Metal prototypes are usually manufactured by cnc machining, cnc turning, sheet metal & laser cutting, etc. Metal prototypes are used for a wide variety of industries such as automotive, home appliances, medical devices, computer, vending machines, and so on.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw