What Are The Vacuum Casting Processes?

Vacuum casting is a fast & cost-effective ways of producing a small quantities of high quality rapid prototyping parts. What are vacuum casting processes?

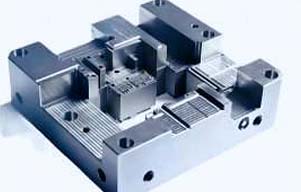

Step 1, Create a mater model

The first step is to make a perfect master model, which is usually created from 3D printing using SLA technologies, some times also made by CNC machining, and polish the surface to the required standard. Texture surface can be done by painting or spraying sanding on the master model. It is important to note that the master sample can withstand temperature up to 40°C.

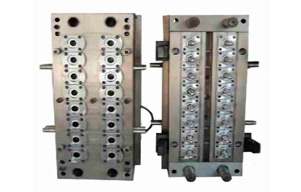

Step 2, Make the silicone mold

Firstly, Suspend the prepared master model into the casting case.

Then carefully pour the silicone into the casting case, in which the silicone flow inside and completely fill every features of the master model. This process is done in a vacuum chamber to remove the air from the silicone and ensure there are no bubbles mould's surface finish.

Once the case is completely filled and the master model is covered by a layer of silicone, the mould is then put into the oven to curve the silicone for around 8-16 hours, depend on the size of the mold.

After the mold is curved, carefully split the mold with a knife, remove the master model out of the mold, and inspect the mould.

Step 3, Pour Polyurethane resin

After mold is assembled and casting funnel is inserted, the mold is taken back to the vacuum chamber. Pour the prepared liquid polyurethane into the silicone mold through the funnel. The vacuum remove the air/gas out of the polyurethane to ensure all details are molded and to avoid the blemish, air bubble on the surface finish. After pouring, the mould is heated to cure the polyurethane under 70-80°C temperature in the heating chamber.

Step 4. De-mould the cast part

After the cured polyurethane has cooled, open the mould, and remove out the cast part. Then cut off the gate and the risers, and trim and clean the parts, then do inspection and surface finishing. The vacuum casting is finished, the product is ready to used. Generally, the lifespan of the vacuum casting mold is 15-20 shots.

What Materials Are Used In Vacuum Casting?

Vacuum Casting resins are available in various hardness and colors, depending on customer's product's requirement. In vacuum casting services, Polyurethanes(PU) is probably the most widely used type of casting resins, it has been applied in various fields, such as electronic, medical devices, agriculture, aerospace, automotive, and so on. PU casting resins are available with extensive properties including various flammability-retardant, elasticity, shore harnesses, temperature resistance and so on. The choosing of the casting resin depends on the product’s application, surface treatment and other requirements.

Choosing from a broad selection of materials, the following are some of the most common casting resins used for vacuum casting projects.

ABS-like

PP-like

PA-like

Glass filled-PA-like

PMMA-like

PC-like

PE-like

TPO- like

Nylon-like

TPU Like

Pur/pu-like

Elastomer-like

The Difference Between CNC Prototyping And Vacuum Casting Prototyping

Both CNC machining prototype service and vacuum casting service are ways to produce rapid prototypes. CNC machining refers to programming by CNC machining language. The cutter on the CNC equipment moves on the material according to the path set by the program, and cuts off excess material to obtain the prototypes of required shapes and sizes. Vacuum casting refers to making simple silicone molds through master patterns, and then replicating the parts. The cost of vacuum casting is low and the cycle is short. So what are the main difference between CNC prototyping and vacuum casting prototyping? Let's take a look bellow:

The materials of CNC prototypes are extensive and can include plastic and metal. Plastic CNC prototyping materials include: ABS, acrylic, PP, PC, POM, nylon, PEI, PEEK, PBT, PTFE and other materials; Metal CNC prototyping materials include: aluminum, stainless steel, copper, steel, iron, etc. The range of materials used for vacuum casting prototypes is relatively narrow, mainly rubber, ABS, PC, PA, PP, and acrylic materials, etc.

The precision of CNC machining prototypes will be much higher than the precision of vacuum casting prototypes. The precision of our CNC machining is generally between 0.02mm-0.05mm, while vacuum casting prototypes may be slightly deformed and shrunk due to thermal expansion and contraction, the accuracy is not so easy to control, generally is around 0.2mm. Therefore, in general, vacuum casting prototype does not have very strict requirements on precision.

CNC machining requires machining step by step, while vacuum casting only needs to make a silicone mold and then replicate the component. Generally, a silicone mold can replicate about 8-15 parts, and the production speed is faster than CNC machining.

Since the CNC machining prototyping needs to be machined step by step, and it takes a certain amount of time to adjust the machine, the cost of the CNC prototype is generally relatively high, while the vacuum casting prototyping can be one-piece forming produced via vacuum mold casting. Therefore, the production cost of Vacuum Casting will be much lower.

The Advantages Of Our Vacuum Casting Services

Our vacuum casting prototyping manufacturing cost is low and production time is short.

Cost effective for Low volume production. After making a master pattern and the silicone mold, it can be duplicated according to the master pattern.

Flexible de-mould operation. After the mold is dry and solidified, the mold is soft and flexible, conductive to cutting and de-mould.

Diverse material and colors for your choosing.

High quality. The defect rate is small. As long as there is no defect on the master pattern, the vacuum casting parts will not be wrong. Most of the time we have avoided it.

Good repeatability, ensure same quality and consistency.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw