Polyurethane Vacuum Casting Process

Polyurethane vacuum casting is a manufacturing process used for low volume production of plastic parts. It involves making a silicone mold of the desired part and then using the mold to cast the part in polyurethane resin.

Here are the steps involved in the polyurethane vacuum casting process:

Design the part: The first step is to design the part that you want to manufacture. This can be done using CAD software or by creating a physical prototype.

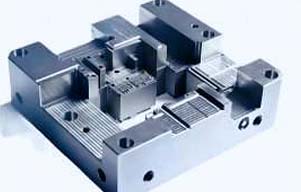

Create a master pattern: Create a master pattern: The next step is to create a master pattern of the part. This can be done using custom CNC machining or additive 3D printing.

Make a silicone mold: Once you have the master pattern, you can use it to create a silicone mold of the part. The mold is created by applying several layers of silicone to the master pattern, which is then allowed to cure.

Cast the part: Once the mold is ready, it is placed in a vacuum chamber and polyurethane resin is poured into the mold. The vacuum helps to remove any air bubbles and ensure that the resin fills the mold completely.

Remove the part: Once the resin has cured, the mold is opened and the part is removed. The part may require some finishing work to remove any excess material or to add any necessary features.

Repeat: The process can be repeated as many times as necessary to produce the desired number of parts.

Polyurethane vacuum casting is ideal for low volume production runs because it is relatively quick and inexpensive compared to other manufacturing processes like fast injection molding. It is also a good option for producing custom precision parts with complex geometries or fine details, as the silicone molds can capture even small features.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw