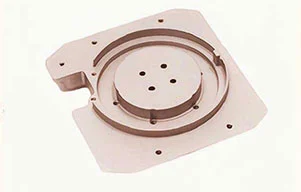

Advantages of Plastic Case ABS Vacuum Casting for Robot Prototype

Vacuum casting is a popular manufacturing process used to create prototypes of plastic parts, including robot cases, using a silicone mold. It is a cost-effective and efficient method for producing small to medium-sized batches of parts with high accuracy and quality.

ABS plastic is a popular choice for vacuum casting because of its strength, durability, and ability to be easily molded. The process begins by creating a master pattern of the robot case, typically using custom CNC machining or additive 3D printing. The pattern is then used to create a silicone mold, which is placed in a vacuum chamber.

The ABS plastic is then poured into the mold under vacuum, ensuring that the plastic fills every detail of the mold. The mold is then cured at a specific temperature and time to harden the plastic. Once cured, the mold is removed, and the plastic part is extracted from the mold.

The resulting plastic case can then be sanded, painted, or finished to match the desired appearance of the final product. Vacuum casting is an effective method for creating high-quality prototypes that closely resemble the final product in both appearance and functionality.

Overall, ABS vacuum casting is an excellent choice for producing robot prototypes due to its ability to produce high-quality, precise, and cost-effective plastic parts. The process allows for rapid iterations and modifications to the design, reducing the time and cost of bringing the final product to market.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw