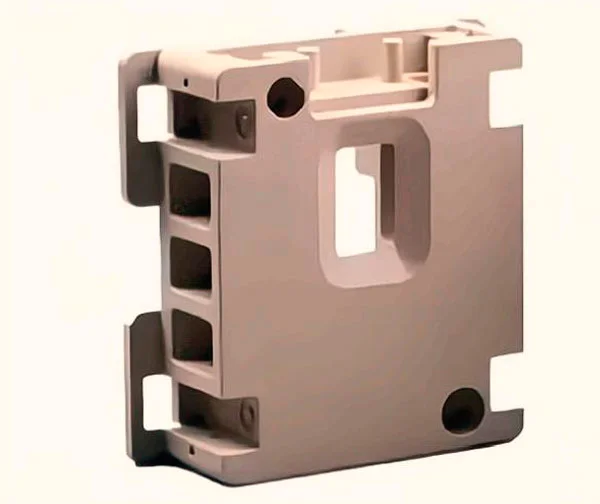

Multiple Use of Peek Machined Parts in Electronic Industry

Precision-machined parts play an important role in the electronic industry, as they are used in the manufacturing of electronic devices and components. Here are some examples of these CNC machining precision parts used in the electronic industry:

Heat sinks: Heat sinks are used to dissipate heat generated by electronic components, such as CPUs, power transistors, and voltage regulators. Heat sinks are typically made from aluminum or copper and require precision machining to achieve the necessary thermal performance.

Connectors: Connectors are used to establish an electrical connection between two or more electronic components. Examples of connectors include PCB connectors, battery connectors, and RF connectors. Connectors require tight tolerances and precise machining to ensure a reliable and stable connection.

EMI shielding: EMI shielding is used to prevent electromagnetic interference from affecting electronic devices. EMI shields are typically made from metals such as aluminum, copper, and nickel, and require precision machining to achieve the necessary shape and fit.

Microelectronics components: Microelectronics components, such as transistors, diodes, and capacitors, require precise machining to achieve the required dimensions and tolerances. Precision machining is necessary to ensure the proper functioning of these components.

LED components: LED components, such as heat sinks, reflectors, and lenses, require precise machining to achieve the required shape and surface finish. LED components are often made from aluminum or other materials with good thermal conductivity to help dissipate heat generated by the LED.

In summary, precision-machined parts play a critical role in the electronic industry and are used in a wide range of applications. These parts require tight tolerances, precise machining, and a high degree of accuracy to ensure their proper functioning and reliability.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw