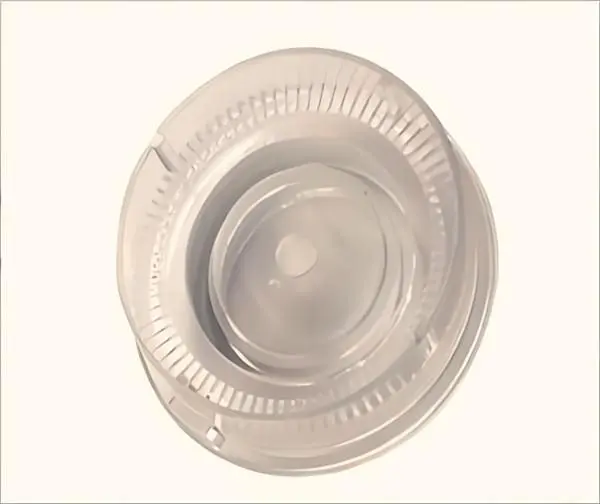

Advantages of Doing Gold Plating on Brass Turning Parts and Brass Machined Parts

There are several reasons for gold plating on brass parts, including:

Aesthetics: Gold plating gives brass CNC parts a shiny, luxurious look. This is often used for decorative purposes, such as jewelry or high-end home furnishings.

Corrosion Resistance: Gold is highly resistant to corrosion, so gold plating can protect brass machined parts from rust and other forms of corrosion.

Conductivity: Gold is an excellent conductor of electricity, so gold plating can improve the conductivity of brass turned parts. This is often used for electrical contacts, such as in electronic equipment.

Wear resistance: Gold is a very hard metal, so gold plating can improve the wear resistance of brass machined parts. This is useful for parts that are subject to a lot of friction or wear.

Overall, gold plating on brass turned parts and brass machined parts are part of CNC machining precision parts that offer a range of functional and aesthetic advantages, making them ideal for many applications.

Why Choose Our Gold plated Brass turning parts Small batch CNC Turning

Precision:

Our Brass CNC turning services use advanced CNC turning machines, which can create parts with high precision and accuracy and are highly recommended by precision machining suppliers. This allows complex geometries and tight tolerances to be achieved, ensuring parts fit together perfectly.

Efficiency

Our Brass turning services can produce high volumes of parts quickly and efficiently, which saves your time and money.

Versatility

We can handle a variety of different brass alloys, allowing for the production of a wide variety of brass turned parts. This makes it an excellent choice for a variety of applications.

Custom

Our Brass turning services can create custom parts to meet specific design requirements, from prototype cnc turning, small batch cnc turning, to mass production. This allows for greater design flexibility and ensures parts are tailored to your specific needs.

Low Cost

Brass is a relatively inexpensive material, and our brass CNC turning services can produce parts at a lower cost than other manufacturing methods.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw