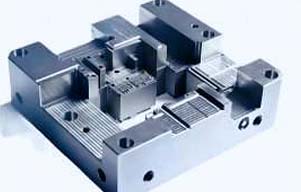

An Array of Surface Finishes on OEM Precision Machined Components CNC Aluminum Mechanical Parts

1. Polishing. The polishing of aluminum parts can remove the knife marks and some defects and burrs left in the process of CNC machining, and make the surface of aluminum machined parts bright.

2. Sandblasting. The purpose of sandblasting aluminum parts is to cover up some defects in the machining process, so as to meet some special requirements of customers for the appearance of parts. Sandblasting materials include glass sand, tungsten sand, etc., showing different surfaces and textures.

3. Metal plating. Metal plating is a common surface treatment method for aluminum machined parts, including galvanizing, chrome plating, gold plating, nickel plating, copper plating, etc.

4. Lathe texture. The pattern is processed by a lathe, so that the aluminum parts show a very regular texture as a whole.

5. Brushing. The performance is similar to the lathe texture, which forms a smooth continuous pattern on the surface. The difference is that the car pattern appears as a ring pattern, while the brushing appears as a straight line.

6. Anodizing (coloring): There are two main functions of anodizing aluminum machined parts, one is to enhance physical properties, and the other is to color aluminum parts according to customer requirements.

Advantages of Our OEM Precision Machined Components CNC Aluminum Mechanical Parts

Integrated Manufacturing Solutions

From precision rapid prototyping, custom CNC machining, CNC turning, fabrication, surface treatment, assembly, packaging to international shipping

Quality Assurance

We have a professional team to control the quality, and also a team of experienced CNC programming engineers and machinists

Considerate customer service

There are dedicated personnel to provide timely custom precision machining service and technical support for each customer

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw