Advantages of Custom CNC Machining Robot Products Prototypes

Custom CNC machining of robot products prototypes involves the use of computer-controlled machines to create precise and complex components that can be used in the design and development of robotic systems. CNC machining allows for the production of high-quality prototypes with tight tolerances and repeatable accuracy, which is critical in the development of robotics technology.

During the CNC machining process, a computer program is used to control the movement of cutting tools, which removes material from a workpiece to create the desired shape and dimensions of the component. CNC machining is capable of producing a wide range of shapes and sizes, including complex geometries, such as curved surfaces, pockets, and cavities.

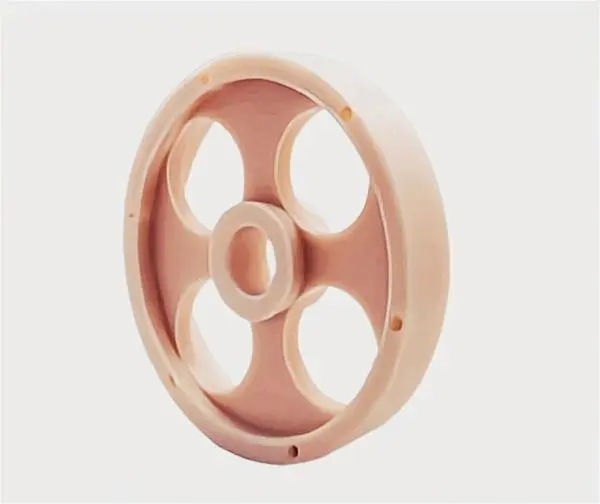

Custom CNC machining of robot product prototypes can be used to create a wide range of components, including:

Robot arms and end-effectors: CNC machining can produce the complex shapes and precise tolerances needed for robot arms and end-effectors.

Sensors and control components: CNC machining can create precise components for sensors and control systems used in robotics.

Gearboxes and transmission components: CNC machining can produce the intricate shapes and precise tolerances required for gearboxes and transmission components used in robotic systems.

Structural components: CNC machining can create strong and durable structural components for robots, such as chassis and frames.

YS Rapid is a experienced precision machining manufacturer which custom CNC machining various kinds of rapid prototypes for robot products in a reliable and efficient process that allows for the production of high-quality custom precision parts with precise dimensions and tolerances, enabling the development of advanced robotic systems.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  ar

ar  tr

tr  iw

iw