Rapid prototyping and small batch manufacturing have revolutionized the way products are developed and produced. These processes allow for quick and cost-effective production of prototypes and small quantities of parts, which can be crucial in industries such as aerospace, automotive, medical devices, and consumer goods. However, the quality of the final product can be affected by various factors that need to be considered during the prototyping and manufacturing process.

Design of the CNC machining prototyping parts

The design of the part is the first and most crucial factor affecting the quality of rapid prototyping and small batch manufacturing. The design needs to be precise and accurate to ensure that the final product meets the required specifications. A poorly designed part can result in a defective product or even lead to the failure of the entire project. The design should be optimized for the chosen manufacturing method, whether it is rapid prototyping or CNC machining service.

Material for CNC machining prototyping

The choice of material for rapid prototyping and small batch manufacturing is also a critical factor in ensuring the quality of the final product. The material should be suitable for the specific application and manufacturing process. For example, some materials may not be compatible with rapid prototyping technologies such as 3D printing or injection molding. The material should also meet the required mechanical properties, such as strength, durability, and heat resistance. Using high-quality materials can ensure the final product meets the required specifications and is fit for its intended purpose.

Manufacturing process used in CNC machining prototyping

The manufacturing process used in rapid prototyping and small batch manufacturing can significantly impact the quality of the final product. Different manufacturing methods have different advantages and limitations that need to be considered. For example, 3D printing is a popular rapid prototyping method, but the final product may not have the same mechanical properties as those produced using traditional manufacturing methods such as CNC machining service. The manufacturing process should be optimized for the specific part, taking into consideration factors such as tolerances, surface finish, and accuracy.

Post-processing of CNC machining prototyping

Post-processing is another critical factor affecting the quality of rapid prototyping and small batch manufacturing. The final product may require additional processes such as finishing, painting, or assembly. These processes can significantly impact the final quality of the product. For example, surface finishing can improve the appearance and texture of the product, while assembly may require precise alignment and fitting. Post-processing should be carefully planned and executed to ensure that the final product meets the required specifications.

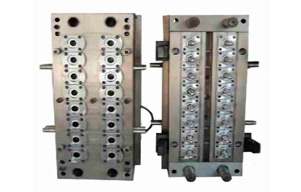

Equipment used in CNC machining prototyping

The equipment used in rapid prototyping and small batch manufacturing can also affect the quality of the final product. The equipment should be capable of producing parts that meet the required specifications and tolerances. Using outdated or inadequate equipment can result in defective products, which can be costly in terms of time and resources. Choosing the right equipment for the specific part and manufacturing process is essential to ensure the quality of the final product.

The experience and expertise of the team involved in rapid prototyping and small batch manufacturing can also affect the quality of the final product. The team should have a thorough understanding of the design, manufacturing process, and materials used. They should also have experience in troubleshooting and resolving issues that may arise during the prototyping and manufacturing process. Having an experienced team can ensure that the final product meets the required specifications and is of high quality.

In conclusion, several factors can affect the quality of rapid prototyping and small batch manufacturing. These factors include design, material, manufacturing process, post-processing, equipment, and experience. Addressing these factors during the prototyping and manufacturing process can ensure that the final product meets the required specifications and is of high quality. Rapid prototyping and small batch manufacturing can offer significant advantages in terms of time and cost savings, but it is essential to consider the quality factors to ensure the final product meets the intended purpose.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw

.jpg)