The Usage of Small Batch Production Electronic Prototype Vacuum Casting Plastic Parts

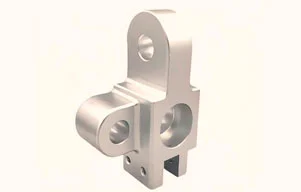

Vacuum Casting is an essential process in the field of product development and prototyping for new products, especially for electronic products. The process of making the precision mechanical parts involves creating a prototype of an electronic product using a vacuum casting method.

The electronic prototype vacuum casting process allows designers and engineers to create a functional prototype of an electronic product quickly and cost-effectively. This is achieved by using a vacuum to pull liquid material, such as silicone, into a mold, which creates a replica of the desired electronic part or product.

The role of electronic prototype vacuum casting is to help engineers and designers develop and test electronic products in a faster and more efficient manner. By creating a functional prototype quickly, designers and engineers can identify and address any issues or problems with the design before moving onto the production phase. This can help to save time and money in the long run, as well as ensuring that the final product is of the highest quality.

Another important role of electronic prototype vacuum casting is to enable manufacturers to produce small runs of electronic products. This is particularly useful for companies that need to produce small batches of products for testing or for marketing purposes.

Overall, as an important type of China precision machining, the electronic prototype vacuum casting process is an essential part of the product development and prototyping process for electronic products, helping designers and engineers to create functional prototypes quickly and efficiently, and enabling manufacturers to produce small runs of products for testing and marketing purposes.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw