Benefits of Custom Machining Hardware for Beauty Equipment

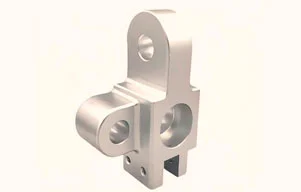

Beauty equipment hardware custom machining refers to the process of using computer-controlled machines to create custom parts or products for beauty equipment hardware. This may involve creating parts such as housings, handles, knobs, or other hardware components that are required for beauty equipment.

CNC machining is a common method for creating custom precision parts for beauty equipment hardware. And the followings are some significant advantages of using custom machining to manufacture beauty equipment hardware:

Highly custom made: CNC machining allows for the creation of custom designs and shapes, which is important for beauty equipment hardware that requires specific dimensions or features.

Broad material selection: CNC machining can be used with a wide range of materials, including metals, plastics, and composites, allowing for flexibility in material selection.

High precision: CNC machining offers high precision and accuracy, ensuring that the final product meets exact specifications.

Strength and durability: CNC machining can produce parts with high strength and durability, which is important for beauty equipment hardware that needs to withstand frequent use.

Fast-turnaround: CNC machining is a fast method for creating custom parts, which is important for beauty equipment hardware where speed-to-market can be critical.

Cost-effective: CNC machining can be a cost-effective method for creating custom parts in small to medium-sized production runs, as it eliminates the need for expensive tooling and molds.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw