- Plastic Rapid Prototyping

- Metal Rapid Prototyping

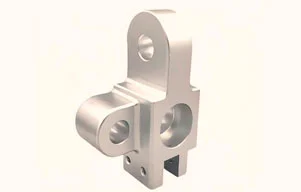

- CNC Prototyping

- Silicone Rubber Prototyping

- CNC Turning

- Custom CNC Milling Service

- CNC 3-axis Machining

- CNC 4-axis Machining

- 5-Axis CNC Machining Service

- SLA (Stereolithography) 3D Printing

- SLS (Selective Laser Sintering) 3D Printing

- SLM 3D Printing

In the competitive world of manufacturing, the ability to produce high-quality parts quickly and cost-effectively is crucial. Rapid injection molding (RIM) has emerged as a powerful technique that add...

View More

What are you looking for?

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw