The Benefits of Using 4 Axis Milling for Machining Aluminum Parts

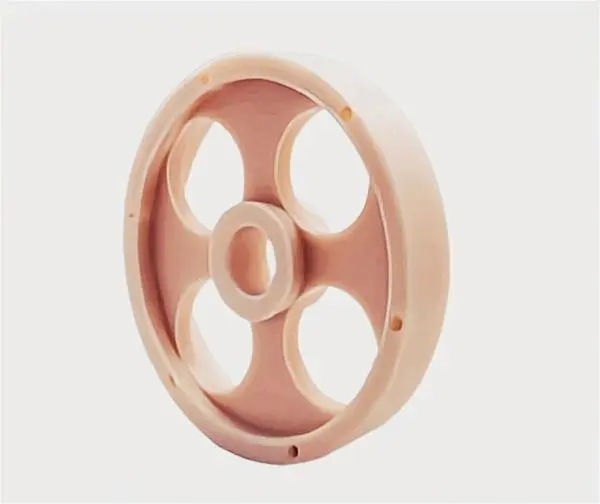

Custom 4-axis milling for precision mechanical aluminum parts involves using advanced computer-controlled machinery to create intricate designs and shapes with high precision. The process involves cutting, drilling, and shaping aluminum parts to exact specifications using four axes of motion. This allows for the creation of complex shapes and designs that would be difficult or impossible to achieve using traditional machining methods.

Some of the benefits of using custom 4-axis milling for precision mechanical aluminum parts include:

High Precision: Custom 4-axis milling allows for the creation of highly precise mechanical parts with tolerances as low as 0.0005 inches. This level of precision is essential in industries such as aerospace, medical equipment, and robotics, where even the smallest deviations can have serious consequences.

Customizability: Custom 4-axis milling allows for the creation of parts with complex geometries and designs that cannot be produced using traditional machining methods. This means that manufacturers can create highly customized parts to meet the specific needs of their clients.

Faster Production: Custom 4-axis milling allows for the creation of parts in a shorter amount of time than traditional machining methods. This is because the process is fully automated, allowing for faster and more efficient production.

Cost-effective: Custom 4-axis milling is a cost-effective way to produce high-precision parts. This is because the process is fully automated, reducing labor costs and minimizing the risk of errors and defects.

To sum up, custom 4-axis milling for precision mechanical aluminum parts offers a range of benefits for manufacturers in a variety of industries. By leveraging the power of advanced computer-controlled machinery, manufacturers can create highly precise, customized, and cost-effective parts to meet the specific needs of their clients.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw