Considerations of Rapid Prototyping High Precision Custom 304 Stainless Steel Parts

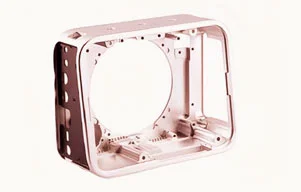

Rapid prototyping of high precision custom 304 stainless steel parts is a process of quickly producing prototypes of parts with high dimensional accuracy and complex geometries. 304 stainless steel is a commonly used material in various industries due to its excellent corrosion resistance, high-temperature resistance, and good weldability. Here are some important considerations when producing rapid prototype high precision custom 304 stainless steel parts:

Material selection: The choice of 304 stainless steel is essential when producing prototypes. The material should be selected based on the specific requirements of the part and the application.

3D modeling and CAD design: A 3D model of the part is created using Computer-Aided Design (CAD) software. The 3D model is used to program the CNC machine to produce the part.

CNC machining: CNC machining is a process of removing material from a workpiece using computer-controlled machines. It is an ideal method for rapid prototyping of high precision custom 304 stainless steel parts due to its ability to produce complex geometries and tight tolerances.

Quality control: Quality control is critical to ensure that the produced parts meet the required specifications and standards. Inspection procedures should be in place to verify the accuracy and quality of each part.

Surface finish: The surface finish of the prototype part is important, as it can affect the overall quality of the part. A smooth surface finish is desired for parts used in applications where cleanliness and hygiene are important, such as in medical or food processing equipment.

Overall, the rapid prototyping of high precision custom 304 stainless steel parts requires specialized knowledge and expertise in CNC machining and quality control. It is important to work with a qualified and experienced manufacturing professional to ensure that the parts meet the required specifications and standards. Rapid prototyping of custom parts allows for quick iterations and modifications to the design, ultimately leading to more efficient and effective final product designs. Our company is professional rapid prototype manufacturer, we are capable of manufacturing prototypes from a variety of materials including stainless steel, aluminum, brass, bronze, abs, pc, pei, peek, pom, foam, and so on. If you have a new inquiry or any questions about our service, please don’t hesitate to contact us.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw