Introduction Of The ABS Material

ABS plastic is a terpolymer of three monomers, acrylonitrile (A), butadiene (B) and styrene (S). The relative content of the three monomers can be changed arbitrarily to make various resins.

ABS plastic has the common properties of three components, A makes it resistant to chemical corrosion, heat resistance, and has a certain surface hardness, B makes it have high elasticity and toughness, and S makes it have the processing and molding characteristics of thermoplastics and improve electrical properties. performance. Therefore, ABS plastic is a kind of "tough, hard and rigid" material with easily available raw materials, good comprehensive performance, low price and wide application. ABS plastic has been widely used in machinery, electrical, textile, automobile, aircraft, ship and other manufacturing industries and chemical industry.

The Advantages of ABS Prototypes

1. Good mechanical and thermal properties, high hardness, easy metal plating on the surface;

2. Fatigue resistance and stress cracking resistance, high impact strength;

3. Chemical corrosion resistance such as acid and alkali; low price; processing, molding, modification easy.

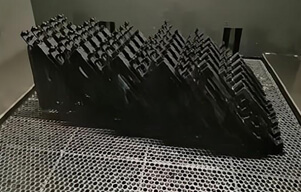

Applications Of Customized CNC Machined ABS Prototype

Customized Cnc Machined Abs Prototype is commonly used in a variety of structural parts, such as machine covers, enclosure, instrument casings, hand drill casings, fan impellers, casings such as radios, telephones and television, some electrical parts, auto parts, machinery and conventional weapons parts, etc.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw