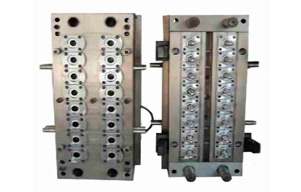

Both CNC machining prototype service and vacuum casting service are ways to produce rapid prototypes. CNC machining refers to programming by CNC machining language. The cutter on the CNC equipment moves on the material according to the path set by the program, and cuts off excess material to obtain the prototypes of required shapes and sizes. Vacuum casting refers to making simple silicone molds through master patterns, and then replicating the parts. The cost of vacuum casting is low and the cycle is short. So what are the main difference between CNC prototyping and vacuum casting prototyping? Let's take a look below:

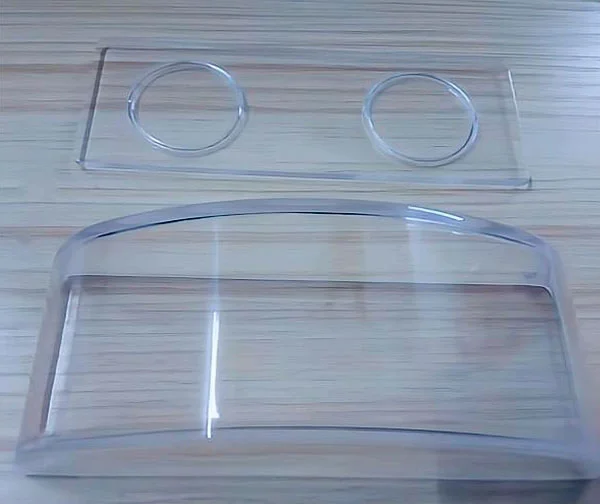

The materials of CNC prototypes are extensive and can include plastic and metal. Plastic CNC prototyping materials include: ABS, acrylic, PP, PC, POM, nylon, PEI, PEEK, PBT, PTFE and other materials; Metal CNC prototyping materials include: aluminum, stainless steel, copper, steel, iron, etc. The range of materials used for vacuum casting prototypes is relatively narrow, mainly rubber, ABS, PC, PA, PP, and acrylic materials, etc.

The precision of CNC machining prototypes will be much higher than the precision of vacuum casting prototypes. The precision of our CNC machining is generally between 0.02mm-0.05mm, while vacuum casting prototypes may be slightly deformed and shrunk due to thermal expansion and contraction, the accuracy is not so easy to control, generally is around 0.2mm. Therefore, in general, vacuum casting prototype does not have very strict requirements on precision.

CNC machining requires machining step by step, while vacuum casting only needs to make a silicone mold and then replicate the component. Generally, a silicone mold can replicate about 8-15 parts, and the production speed is faster than CNC machining.

Since the CNC machining prototyping needs to be machined step by step, and it takes a certain amount of time to adjust the machine, the cost of the CNC prototype is generally relatively high, while the vacuum casting prototyping can be one-piece forming produced via vacuum mold casting. Therefore, the production cost of Vacuum Casting will be much lower.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw