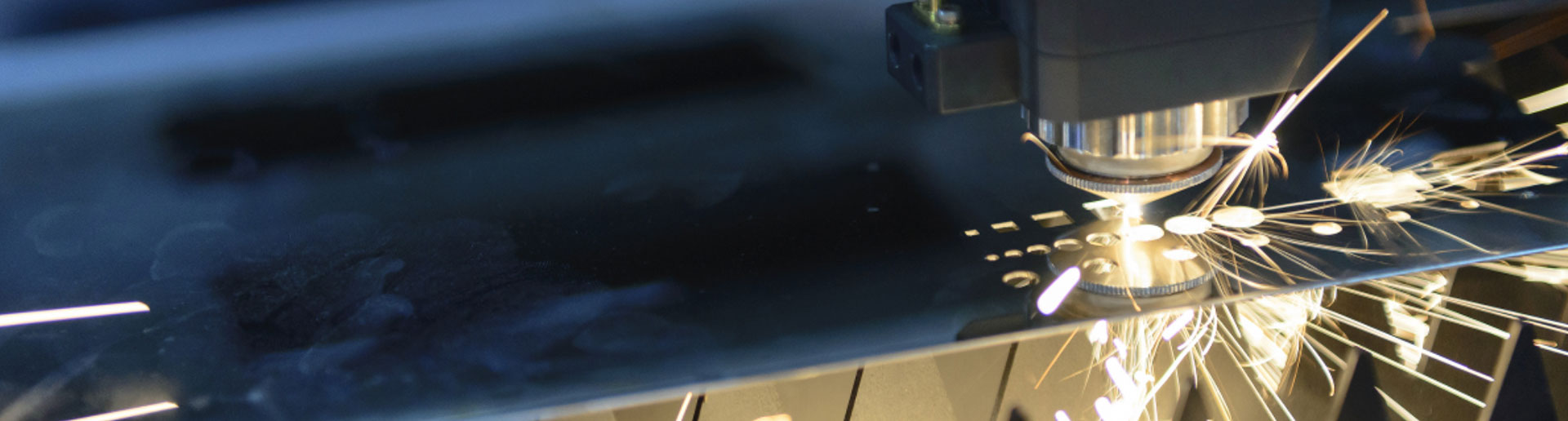

The thickness of agricultural machinery sheet metal processing parts is generally 2-6mm metal plate, and this thickness of sheet metal is exactly the thickness of sheet metal laser cutting. There are many advantages to using sheet metal cutting to manufacture agricultural parts, such as fast cutting speed, small footprint, and a high degree of flexibility. The sheet metal parts of the equipment can be cut and processed at any time, which greatly shortens the cycle of equipment from prototype to mass production.

In recent years, the agricultural machinery industry has developed rapidly, and agricultural machinery equipment has shown a trend of diversification and automation. Sheet metal laser cutting can use modern CAD and other software to realize plate cutting of any shape. Using laser cutting processing not only has fast processing speed, high efficiency, and low cost but also avoids tool replacement and shortens the production preparation time cycle. It is easy to realize continuous processing, and the laser beam transposition time is short, which improves production efficiency. Various workpieces can be installed alternately. When a workpiece is processed, the completed parts can be removed and the workpiece to be processed can be installed to realize parallel processing.

Our Strength of Sheet Metal Fabricating Agricultural Parts

YS Rapid Provides one-stop custom sheet metal fabrication services for agricultural equipment, from sheet metal laser cutting, sheet metal folding, welding, assembly, and final surface finish to beatify the products.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw