We have extensive experience in CNC machining of many materials, such as SUS304, AISI303, S316, AL6061, FR4, Brass, ABS, PC, POM, PA, PTFE, PEI, PEEK and other materials.

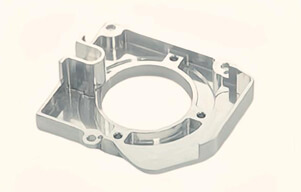

We have advanced CNC milling machine, automatic lathe and other equipment, and can provide CNC machining, CNC milling and CNC turning parts. Our customers can obtain professional customized cnc machining services from the first contact to the final delivery.

Over 10 years of experience in the industry brings us a complete expertise in CNC machining that can help us serve any client to rapid machining of complex and difficult curved features and structural parts.

With 100% quality inspection from start to finish, we implement rigorous procedures to deliver precision CNC machined parts.

With our automatic production, and professional production management,we are able to optimize the processing to control the cost of manufacturing.

We support any order quantity, whether it is 1 piece or 1000 pieces, we will complete it carefully and deliver it to customers on schedule with high quality.

We can provide not only various materials cnc machining services which meets complex design specifications, but can also provide complete range of surface finishes such as anodizing, painting, polishing, powder coating, sandblasting, plating, and so on.

We provide one-stop cnc machining services in metal and plastic wiht over 50+materials. Our CNC machining services encompass precision cnc turning, cnc milling, cnc drilling and cnc tapping and so on to meet your part design requirement.

We are a professional custom metal and plastic cnc machining parts manufacturer. Our custom cnc machining parts are widely used in a variety of industries, including automotive, medical devices, electronics, telecommunication, military, aerospace, and so on.

If you have any inquiry, or any question about our CNC machining service, our professional team of sales and engineering will give you quick response within hours. With our over 10 years of manufacturing experience, we can provide you comprehensive manufacturing solution for your custom parts machining.

Most of the time, we provide instant quotation within 24 hours. And we offer quick turnaround CNC machining services of any complexity for both production machined parts and and machined prototypes. We can produce machined prototype parts within 3 days, and complete production machined parts within as fast as 7 to 10 days.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw