In the product R&D process, prototypes making is an important element. The progress from pure manual prototype making to semi-mechanized prototype making to modern 3D printing prototype making is a microcosm of the progress of modern manufacturing technology. So what can 3D printing services help in product design process?

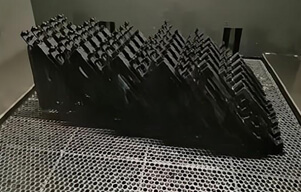

3D printing helps product designers rapidly produce parts with very complicated structures and features which are impossible to produce by traditional manufacturing.

Unlike traditional manufacturing processes that create waste metal/plastic when producing each product, 3D printing only needs a single 3d printing process without changing any features of the design, which does not add extra cost or extra time to produce the final product. In addition, 3D printing does not require a centralized and fixed manufacturing workshop, it greatly simplifies the production process, also 3D printing is simple to operate, which effectively reduce manufacturing cost and labor cost. The process ultimately helps keep the fixed cost and operating cost to minimum.

One remarkable benefit from 3D printing is that it is highly customized. 3D printing no longer focuses on standard size manufacturing like conventional manufacturing processes which needs cutting tools, fixtures, machine tools or molds. 3D printing allows you easily custom print the physical products from 3D CAD graphics of any complicated shape in hours without adding manufacturing cost.

3D printing services can automatically, quickly, directly and accurately convert the 3D design of any specifications into a physical model, and even directly manufacture parts, therefore effectively shortening the time of prototyping and R&D, helping the product innovator to test and launch the products faster than traditional manufacturing process.

3D printing is an additive manufacturing process creating the product by adding materials layer by layer which helps cut raw material waste during the product. And most of these waste raw materials can be recycled to create the 3D printed parts, which improves the utilization of materials and reduce material waste.

EN

EN

jp

jp  ko

ko  fr

fr  de

de  es

es  it

it  pt

pt  tr

tr  ar

ar  iw

iw